Read:3193 Author:admin Publish Time: 01-03-2023

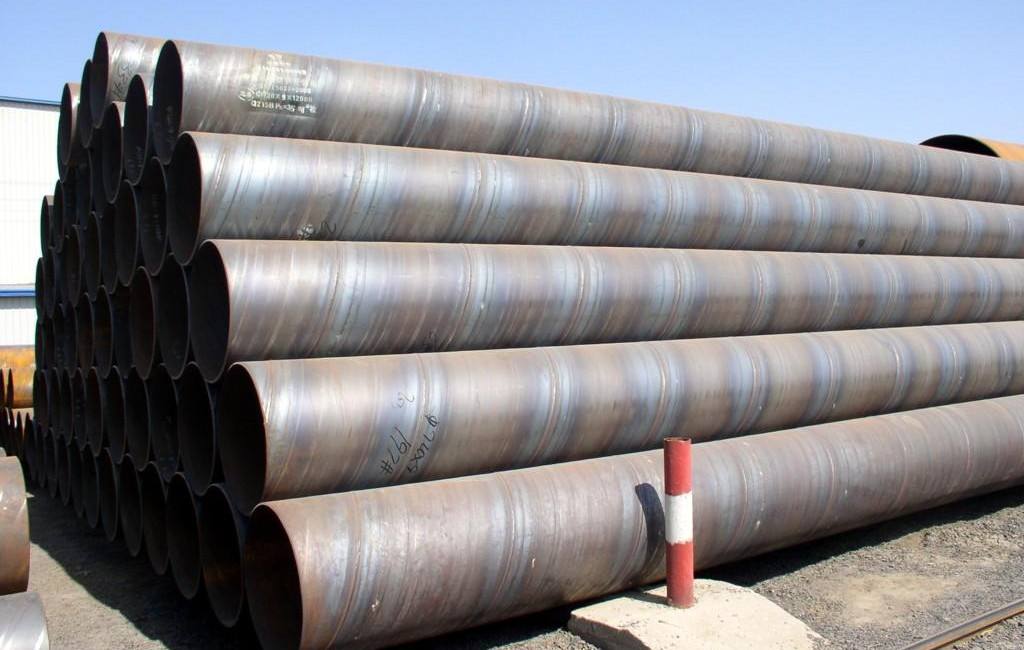

Spiral pipe is also called spiral steel pipe or spiral welded pipe. It take steel strip coil as raw material, through normal temperature extrusion molding, welded by automatic double wire double-sided submerged arc welding process

The spiral welded pipe is mainly used for the pipeline of oil and natural gas, and its specifications are expressed by the outer diameter * wall thickness. Spiral welded pipe shall ensure that the hydrostatic test, the tensile strength and cold bending performance of the weld joint are in compliance with the regulations.

Here introducing the spiral welded pipe manufacturing process:

1.The Raw materials are steel strip coil, welding wire and flux. All materials should be take Strict physical and chemical testing before input.

2.The strip head and tail are butt jointed, adopt single wire or double wire submerged arc welding , after the steel pipe is rolled,using automatic submerged arc welding to repair welding

3.Before forming, the strip is leveled, trimmed, planed, surface cleaned and pre-bent.

4.Using electric contact pressure gauge to control the pressure of the cylinder on both sides of the conveyor, to ensure the smooth conveying of the strip.

5.Adopt external control or internal control to roll molding.

6.Using the weld gap control device to ensure that the weld gap meets the welding requirements, and the spiral welded pipe diameter, the amount of misalignment and the weld gap are strictly controlled.

7.Both internal and external welding are performed by single-wire or double-wire submerged arc welding using a Lincoln welding machine of United States to obtain stable welding specifications.

8.The finished welds were inspected by the on-line continuous ultrasonic automatic flaw detector, ensuring 100% coverage of the spiral welds in nondestructive testing.If there are defects, automatic alarm and spray mark, so the production worker adjusts the process parameters at any time to eliminate defects in time.

9.The spiral welded pipes are cut into individual pieces using the air plasma cutting machine.

10. The first three pieces spiral welded pipe of each batch shall be strictly inspected,include the mechanical properties, chemical composition, bonding condition, surface qualityand non-destructive testing, to ensure that the spiral welded pipe making process is qualified before being formally put into production.

11.The part of the weld with continuous acoustic flaw detection marks, after manual ultrasonic and X-ray review, If there is any defect on the spiral welded pipe, after repair, it shall be subject to nondestructive inspection again after repair until the defect is confirmed to be eliminated.

12.The spiral welded pipe where the butt weld of strip steel and the t-joint intersecting of spiral weld are located are all inspected by X-ray television or film.

13.Each spiral welded pipe is subjected to hydrostatic pressure test and the pressure is radially sealed. The test pressure and time are strictly controlled by the steel pipe water pressure microcomputer detection device.

14.The spiral welded pipe end is machined to ensure accurate control of the end face perpendicularity, groove angle and blunt edge.

Surface treatment method of spiral welded pipe:

1.Cleaning

Use solvent and emulsion to clean spiral welded pipe surface, to remove oil, grease, dust, smoothing agent and similar organic matter, but it can not remove the rust, oxide skin, flux, etc. of the steel surface, so it is only used as an auxiliary measure in the anti-corrosion production of spiral welded pipe.

2.Tool rust removal

Firstly, the spiral welded pipe surface is polished with tools such as wire brushes to remove loose or raised scale, rust, welding slag, and the like. The rust removal of the hand tool can reach the Sa2 level, and the rust removal of the power tool can reach the Sa3 level. If the spiral welded pipe surface is attached with a strong iron oxide scale, the rust removal result of the tool is not ideal, and the anchor depth required for the anti-corrosion construction cannot be achieved.

3.Pickling

Ordinary use of chemical and electrolytic methods for pickling disposal, pipeline anti-corrosion of spiral welded pipe only chemical pickling, can remove oxide scale, rust, old coating, and sometimes can be used as sandblasting after rust removal. Chemical cleaning can make the appearance reach the inevitable cleanliness and roughness, but its anchor pattern is shallow and it is easy to pollute the situation.

4.Abrasive Blasting

Abrasive Blasting is carried out by high-power motor to drive the spray (throwing) blade to rotate at high speed, so that the abrasive such as steel grit, steel shot, wire segment and mineral can be sprayed (throwing) on the surface of the steel tube under the effect of centrifugal force. Not only can rust, oxides and dirt be completely eliminated, but the spiral welded pipe can also reach the required average roughness under the effect of abrasive impact and friction.

After spraying (polishing) and removing rust, not only can the physical adsorption effect of the outer surface of the spiral welded pipe be expanded, but also the mechanical adhesion effect between the anti-corrosion layer and the outer surface of the spiral welded pipe can be enhanced. Therefore, spray (polishing) rust removal is an ideal method for rust removal of pipelines. In general, snd blasting descaling is mainly used for the internal and external treatment of pipes, and shot blasting (sand) descaling is mainly used for surface treatment of pipes.